HOUSE PREFABRICATION

Our technology mainly provides for the prefabrication of walls and roofs in the production hall, and then the assembly of houses, from ready-made elements, on the construction site. It takes about 30 days to prepare the prefabricated elements, and the assembly of the house to the building shell unit takes an average of 3 days. It is erected on a previously prepared foundation.

Prefabrication takes place in the production hall under strict supervision and in the best conditions. This allows us to avoid many mistakes made on construction sites in unfavourable weather conditions. This is a guarantee of timely completion of work, regardless of the weather. In our house factory, advanced full prefabrication is applied, which means we prepare exterior and interior walls, ceilings and roofs.

In the production process installations and thermal insulation are added to the walls. Prefabricated wooden houses are also referred to as finished houses.

All prefabricated elements are processed on modern carpentry machines. Advanced technologies are applied that guarantee perfect accuracy and prompt order completion. Wooden structures and roof trusses are prepared with the specialist Dietrich’s 3D CAD / CAM software. Hundegger carpentry line is used for the production of houses and roof structures.

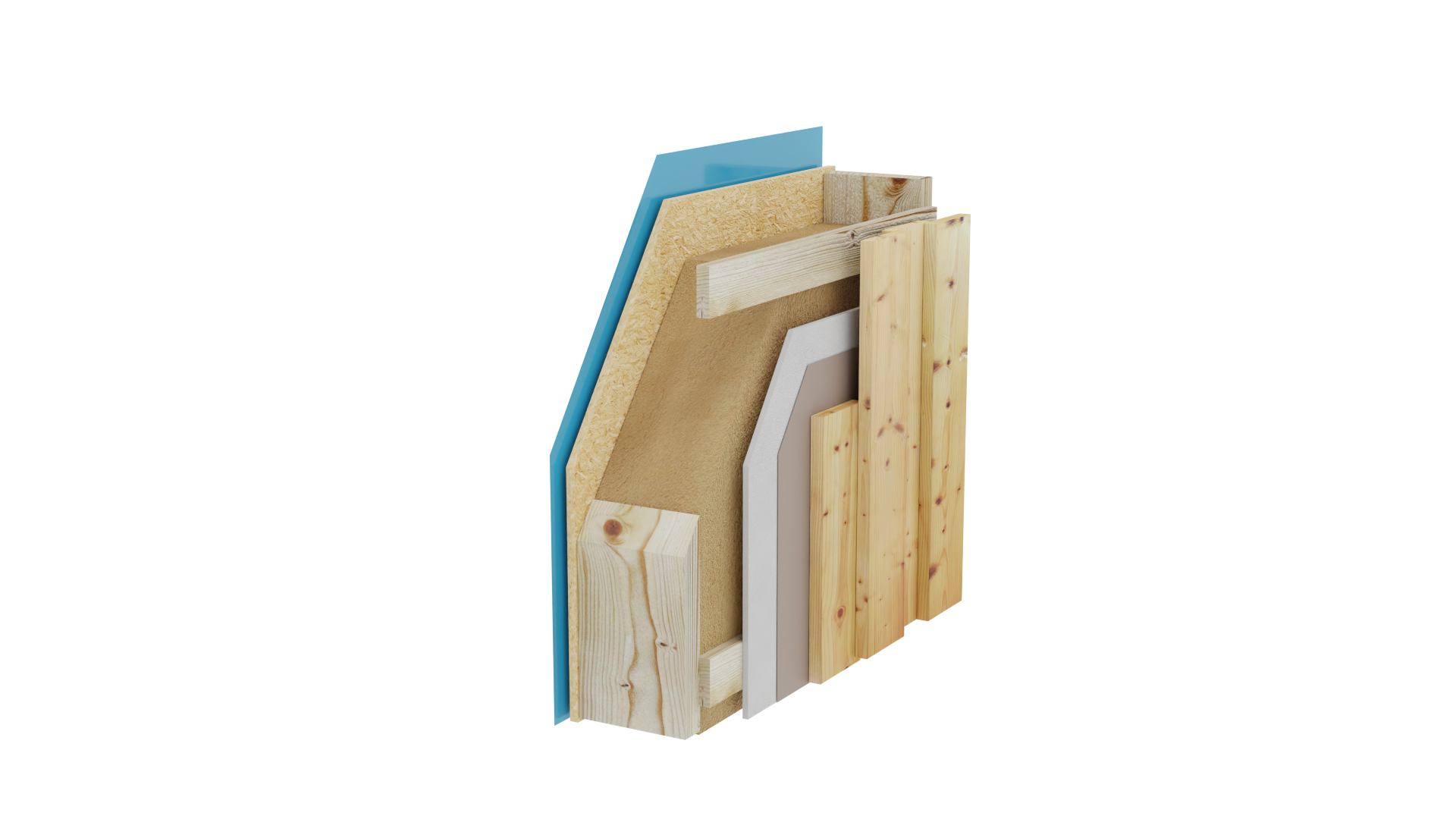

As a standard, the external wall has 26 cm thermal insulation, including 20 cm main insulation made of Steico Zell wood fibre blown between the structure and 6 cm façade insulation made of Steico Protect wood fibre. Glue, mesh and plaster are applied directly to the façade insulation. The structure is made of C24 class spruce beams with a cross-section of 45 x 195 mm. From the inside, sheathing is made of 15 mm thick OSB structure boards and a vapour barrier layer. The finishing is made of fibre-reinforced plasterboards. An external wall with such a cross-section has a heat transfer coefficient of U = 0.15.

Wall thickness: 32.75cm

FINISHING VARIANT1

Horizontal cladding board

FINISHING VARIANT2

Vertical cladding board

FINISHING VARIANT3

Vertical cladding board with overlap

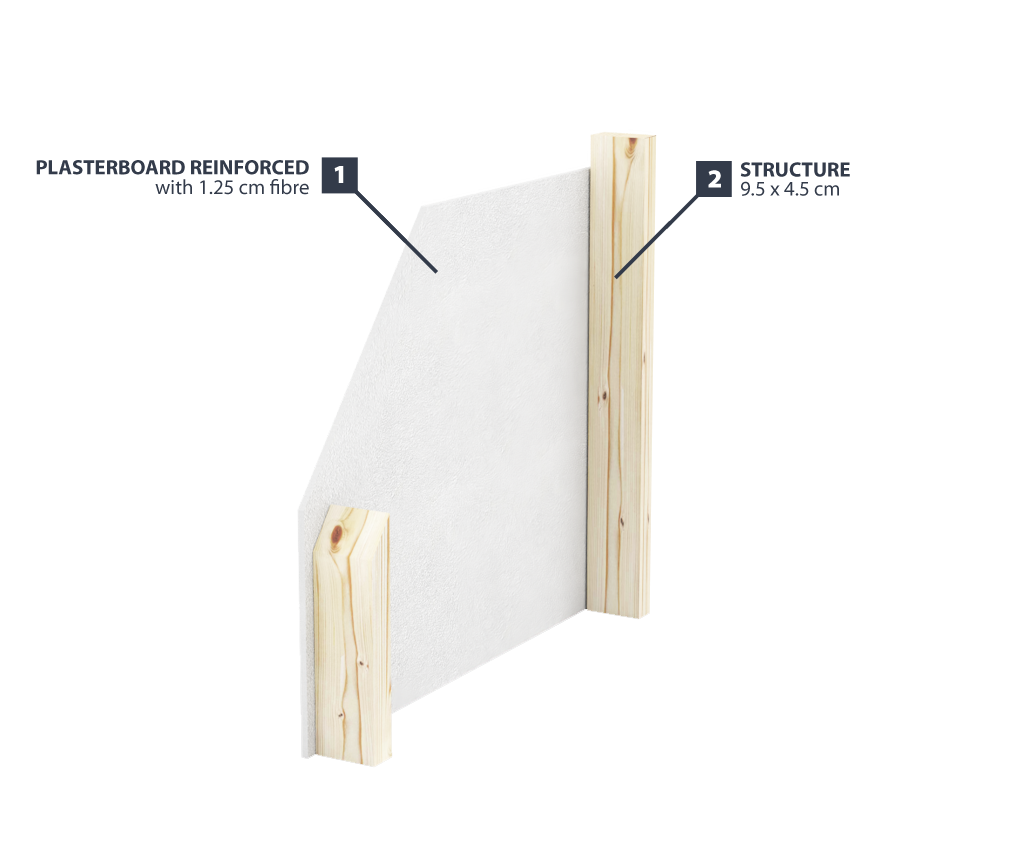

The internal walls are filled with acoustic insulation and sheathed on both sides with fibre-reinforced plasterboard. The structure of the internal walls is made of C24 class spruce beams with a cross-section of 45 x 95 mm.

Wall thickness: 12cm

WALL STRUCTURE

The material used for the construction is Scandinavian spruce – structural certified wood, class C24. The structure of external walls is made of beams with a cross-section of 45 x 195 mm at an axial spacing of 625 mm, and the structure of partition walls is made of beams with a cross-section of 45 x 95 mm at the same spacing. The standard height in the light of the rooms is 260 cm.

ROOF STRUCTURE

The roof structure consists of roof trusses made of C24 timber connected with punch metal plates.

EXTERNAL WALL INSULATION

The outer walls are insulated with STEICO Zell wood fibre in the structure. Outside, there is 6 cm of STEICO Protect façade insulation.

FAÇADE

The STEICO Protect boards are covered with glue.

ROOFING

The roofs are mostly made of steel sheet tiles. The guttering is metal and the soffit is wooden.

WINDOWS

Triple glazed Avante windows with Salamander 6-chamber profile with warm frames and three gaskets are fitted with expansion strips in warm assembly. Alternatively, for an extra fee, Sokółka wooden windows can be ordered. Outside, window sills are made of flat sheet of a colour matching the roof covering.

DOORS

High-class wooden doors, manufactured by Derpal.

FINISHING WALLS WITH PLASTERBOARDS

The internal walls are covered on one side with a fibre-reinforced plasterboard.